In handloading ammunition, there are many variables that need to be controlled to achieve the best accuracy. Bullet weight, diameter of cast bullets and powder charge are just a few examples.

In cartridges loaded with minimal powder charges, the location of the charge at time of ignition can affect accuracy. It has been said that there are some powders that are not position sensitive. The position of the charge in the case might not affect the ignition of the powder, but I believe it does affect accuracy.

I set out to test my theory and got some interesting results. The results of this test don’t prove anything other than how my theory affected the combination I tested.

I loaded 5 rounds of ammunition with and 5 rounds without dacron as a charge column locator. I did this with three powders, all other factors being equal except charge weights. The charge weights were chosen based on the best results of a previous test.

The dacron used was 3/8″ loft quilt batting cut to 1/2″ X 1″ strips and gently tamped over the charges.

Following is the percentage differences in group sizes, according to powder type, and photographs of the targets.

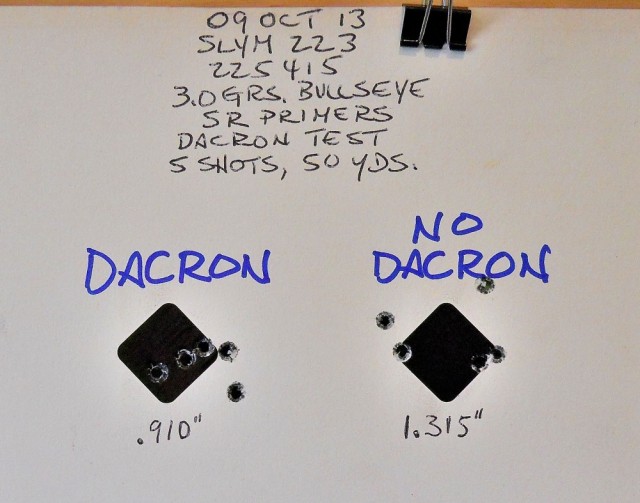

BULLSEYE

NO DACRON- 1.315″

DACRON- 0.910″, GROUP SIZE IS 69% OF NO DACRON GROUP.

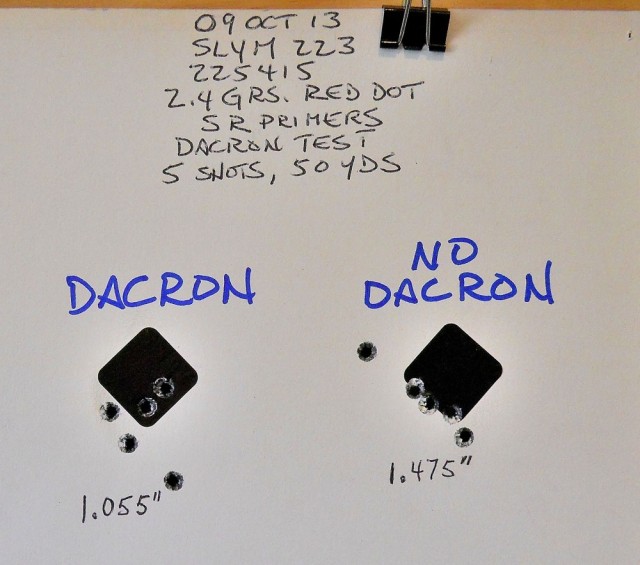

RED DOT

NO DACRON- 1.475″

DACRON- 1.055″, GROUP SIZE IS 71% OF NO DACRON GROUP.

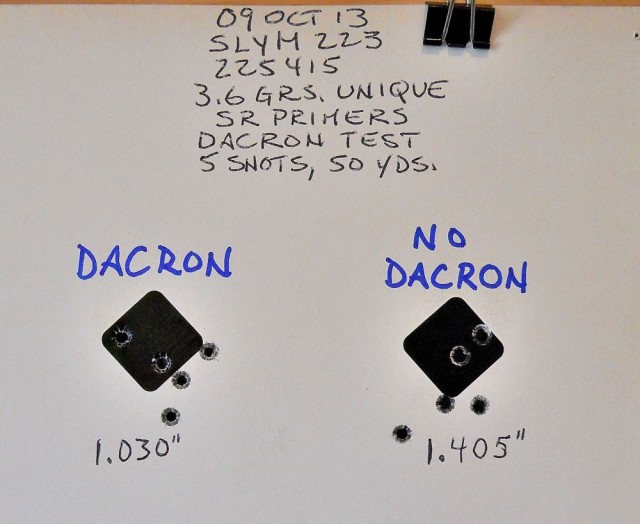

UNIQUE

NO DACRON- 1.405″

DACRON- 1.030″, GROUP SIZE IS 73% OF NO DACRON GROUP.

AVERAGE GROUP SIZE REDUCTION USING DACRON IS 71%.